In a conventional cone or dome speaker, the sound emitter is a cone or dome. The emitter receives acceleration from the voice coil, which is in a magnetic field. An alternating current is passed through the voice coil, the coil oscillates and transmits force to the radiating element.

In a ribbon speaker, the voice coil and transducer are one piece - a conductive ribbon. How is it done and why is it needed?

The picture shows a diagram of a ribbon tweeter.

A conductive emitter ribbon made of metal (most often aluminum) with a thickness of 5 to 50 microns is located between the magnets. An alternating current is passed through it, and it oscillates, emitting sound waves.

This is the main feature of the ribbon tweeter. The absence of "intermediaries" between the voice coil and the emitter allows you to reproduce the finest sound nuances and is noted by listeners as "transparency", "lightness", "holographic".

However, the ribbon has very low resistance. Usually it is tens of milliohms. In order for such a speaker to be connected to a power amplifier designed for a load of some ohms, the ribbon is connected through a step-down transformer, due to which the input impedance of the ribbon speaker at operating frequencies becomes equal to some ohms.

The transformer is usually built into the ribbon speaker. Due to the transformer, the input impedance of the ribbon speaker becomes very small at the lowest frequencies. It is determined by the resistance of the primary winding of the transformer , and usually does not exceed 0.1 ohm. Therefore, if you measure the resistance of the speaker with an ohmmeter, it shows a value close to a short circuit. To correctly measure the input impedance of a ribbon speaker, it is advisable to measure the input impedance curve using special measuring programs - REW , ARTA , LspLAB , etc. Then you can see that in the operating range the input impedance of the tweeter is already a few ohms.

These programs are easy to learn, and if you have started building a speaker system, the ability to work with software will be useful.

For free movement of the ribbon, it must not be placed close to the magnets. If you make the gap small, the ribbon may touch the magnets during operation, deform and distort the sound. If the gap is made too large, then an acoustic short circuit is formed through this gap, and the ribbon will noticeably decrease in recoil with decreasing frequency.

Usually this gap is made in the range from 0.2 to 1 mm, depending on the size of the ribbon. However, this gap seems harmless thing only at first glance.

If you look at the graphs of the level of non-linear distortion depending on the frequency of a ribbon tweeter, you can find an interesting feature. With a decrease in frequency, all, without exception, ribbon tweeters show a monotonous increase in the third harmonic. Below are two examples of different tweeters. The third harmonic is a green graph in the first picture and a black graph in the second.

In these examples, it can be seen that at frequencies below 3-5 kHz, the third harmonic is higher in level than the second harmonic and can reach relatively high values. It turned out that the cause of this "birth disease" of ribbon tweeters is the very gap between the ribbon and the magnets. In the picture, the blue arrows show the movement of air in the gaps between the ribbon and the magnets.

The narrower the gap, the more pronounced this effect of increasing harmonic distortion with decreasing frequency. This effect limits the use of classic ribbons at mid frequencies, and forces the crossover frequency to be shifted up.

To eliminate this effect, Viawave SRT tweeters use a membrane in which the gap between the ribbon and the magnets is covered by a suspension.

The suspension keeps the ribbon moving, but prevents the passage of air flows between the ribbon and the magnets, which greatly reduces the level of the third harmonic. This turned out to be a useful discovery, and we patented this solution.

The nature of the harmonic distortion of the Viawave tweeter SRT-7 is shown in this plot family.

It can be seen that throughout the entire range, the third harmonic plot (black) goes below the second harmonic plot (blue). The level of the third harmonic at 2 kHz is approximately 0.1%.

If the SRT-7 tweeter replaces the SRT membrane with an ordinary corrugated ribbon, then the level of the third harmonic at 2 kHz will increase by about 10-20 times and reach 1-2%. Also, with a conventional ribbon, the return in the mid-frequency region will decrease by 1-3 dB due to acoustic closure between the sides of the ribbon.

Thus, SRT technology expands the capabilities of the ribbon tweeter towards low frequencies, allowing to reduce the crossover frequency, and does not require the developer to use high-order filters. In fact, dome tweeter techniques can be applied to such a tweeter, taking into account the requirements for the safe operation of a specific ribbon tweeter model.

When creating a high-end speaker system, the filters are very carefully tuned. This careful setting is easy to "break" if the speaker parameters are different in the next batch. A new filter setting may be required if the frequency response of the speakers differs from those used when setting up the speakers. This greatly complicates production and is often a headache for high-end loudspeaker manufacturers.

We understand loudspeaker designers very well, which is why our tweeters put a lot of emphasis on repeatability: in pairs, in a batch, and between batches. How is this achieved?

In a ribbon tweeter, the frequency response is very dependent on the filling of the rear chamber, which absorbs the radiation from the back of the ribbon. Often, manufacturers simply cover the walls of the rear chamber with natural felt plates, which absorb sound very well. However, natural felt has a very noticeable variation in parameters from batch to batch and within the same sheet of felt in different places on this sheet. The density changes, and with it the sound absorption coefficient, and, accordingly, the frequency response of the tweeter.

In order to minimize the effects of this natural variation in felt parameters, we apply our chamber filling method.

Felt plates of the desired profile are inserted into the chamber, forming an exact profile of the absorber, independent of the thickness of the felt. In addition, in each tweeter, the total mass of the felt plates is the same, for this they are selected by weight.

The tweeters have different frequency response and different rear chamber design. The membranes are exactly the same.

Chronologically, it happened as follows. First came the GRT-145 with a flat flange. Then the GRT-145W was developed with a waveguide, in which the design of the rear chamber is tuned to take into account the characteristics of the waveguide. We wanted to transfer some findings in the design of the rear chamber of the GRT-145W to the GRT-145. But since the upgrade significantly changed the frequency response of the tweeter, the upgraded version was called SRT-7 to eliminate confusion when ordering.

Structural differences. In the GRT-145 the empty space between the ribbon and the felt is filled with a loose absorber (foam rubber), while in the SRT-7 and GRT-145W this space is sectioned with several baffles. Below are the details for those who are interested.

SRT technology allows the use of a ribbon tweeter in a lower frequency region than classic ribbon tweeters. In SRT tweeters , the recommended crossover frequency is at least 2 kHz for second-order HP filter. This is a very low frequency for a ribbon with an area of only 7 cm2. Therefore, it was necessary to clarify the operation of the membrane at relatively low frequencies in the range from the resonance frequency of the chamber (900 Hz) and one octave higher - up to 2 kHz.

For classical ribbon, this is, in fact, a forbidden range, since the ribbon can be deformed by air flows in the gap, which we constantly write about. And if the crossover point needs to be reduced as much as possible in frequency, then high-order filters (3 and higher) are used to protect the ribbon low frequencies as much as possible.

When operating an SRT membrane at these frequencies, it must be taken into account that the pressure at the ends of the membrane is lower, due to the fact that the magnetic field in these places is weakened. Conditions are created for air flow from the middle part of the membrane with high pressure, to the ends of the membrane, where the pressure is lower. Without going into details, this is a harmful flow and needs to be dampened. In the GRT-145, damping is done by filling the space with foam rubber.

However, when developing the GRT-145 W , it turned out that the foam rubber interferes with the fine tuning of the camera to the characteristics of the waveguide, since it also dampens the air flow from the ribbon into the rear chamber. Therefore, instead of foam rubber, the partitioning of the air space under the ribbon using partitions was used. The baffles dampen the longitudinal air flow under the belt and do not obstruct the air flow into the chamber. This decision formed the basis for the modernization of the GRT-145, from which the SRT-7 turned out.

There will be no references to standards here. This is information for those who are very superficially familiar with the subject and do not find the time or desire to delve into this issue.

As a rule, program power is indicated in datasheets. For example, you can easily find information on the website of a serious manufacturer that a tweeter with a 1" voice coil has a power of 200 watts. What does it mean? This means that the power is measured BEFORE the filter through which the tweeter is connected, that is, it is the power of the entire speaker with an input impedance that does not depend on the frequency in the audio range. At first glance, this is not very fair, but the authors of the standards know better. Usually the filter parameters before the tweeter are specified in the datasheet. In fact, after such a filter, 1/10 - 1/20 of this power gets to the speaker. That is, the real thermal power of such a dome tweeter does not exceed 10-20 W, which is quite consistent with the small size of the voice coil and the conditions for its cooling.

Moreover, 20 W is for the case with magnetic fluid, which improves heat transfer from the voice coil to the magnetic system. Therefore, if you saw in the datasheet of our tweeter a thermal power of 17 W (without any filters), do not be discouraged, this is a relatively high power for a tweeter with a radiator of 7 cm2. And taking into account the real sensitivity of 95-96 dB per 1 W/m, the tweeter can produce a rather high sound pressure. This will be discussed in the next paragraph. The program power of the SRT tweeters is 150 watts with a second-order filter with a cutoff frequency of 3 kHz.

In addition, if we compare two tweeters with a sensitivity of 95 dB/W and 89 dB/W, then to obtain the same sound pressure, the second tweeter needs to be supplied with 4 times more power than the first, since a difference of 6 dB is equivalent to a 2-fold difference in pressure and 4 times in power.

For a better understanding, you need to formulate a simple rule: if the maximum pressure of the loudspeakers in the peaks on the music signal is, for example, 110 dB, then the high-frequency peaks will also reach 110 dB. This is easy to verify if you subject the music tracks to filtering, as a high-pass filter does in a speaker system. In music where there is a drum kit, the peaks on the treble will reach the maximum.

SRT line tweeters withstand pressure in peaks of 120 dB per 1 meter. This is a mechanical limitation. The thermal load on the tweeter will be determined by the frequency and order of the crossover. But in this case, the pressure is limited by the mechanical strength of the membrane. Even if only 2 watts of average thermal power is dissipated on the tweeter, this is quite possible at a high frequency of the crossover point. Anyway, you can not try to "squeeze" more out of the tweeter. 120 dB peak at 1 meter is the limit.

Thus, if you are designing speakers with SRT tweeters , you need to take this into account and do not try to get more than 120 dB pressure from the entire speaker at a distance of 1 meter. It is important to remember that speakers are mechanical devices with limited fatigue strength. And the greater the load on them, the less they have a resource of work.

The GRT-145W tweeter has a waveguide instead of a flat flange. A more appropriate name for this short "horn" is an acoustic lens. Due to the special shape, the waveguide forms a certain phase front of the wave, which achieves the required radiation pattern in a wide frequency range.

GRT-145W waveguide has the greatest influence on the radiation directivity in the horizontal plane of the tweeter. Below are two pairs of charts.

Red graphs - change in frequency response when deviating from the axis by 30 and 60 degrees horizontally for the SRT -7 tweeter.

Blue graphs - change in the frequency response of GRT -145 W under the same conditions.

It is noticeable that up to a frequency of 8-9 kHz, the off- axis frequency response of a tweeter with a waveguide falls off more relative to the on-axis frequency response, compared to the off-axis frequency response of the SRT-7, and above 8-9 kHz, on the contrary, they go above the off-axis frequency response of the SRT-7. In other words, the rolloff of off-axis frequency response with a waveguide is more uniform in frequency, which indicates a more uniform radiation pattern in the operating frequency range. It is narrower up to 8-9 kHz and wider above 8-9 kHz, compared to the SRT-7 ( GRT-145) radiation pattern.

What is the use of all this?

First, due to less off-axis radiation in the midrange, cabinet diffraction has less effect on the frequency response of the tweeter.

Secondly, the listening room will have fewer reflections from walls, furniture, and so on. At the listening position, the direct radiation from the tweeter will more dominate the reflected radiation. This will give you a more accurate and spacious musical image, compared to a flat-flange tweeter in an under-damped room. It is necessary to make a reservation right away that the ribbon themselves build a very voluminous musical image. And the desire for the greatest possible volume and detail is not always justified. Rather, this is the "culinary" task of the speaker designer: to add just enough "seasonings" to the "dish" to make the music interesting to listen to. We produce audio components to solve this creative task.

Thirdly, the GRT-145W waveguide shifts the tweeter deep into the speaker front panel by an additional 15 mm, compared to the SRT -7 and GRT -145 tweeters. In some cases, this helps to find a better phase matching between the midrange and high-frequency bands and simplifies the filter circuit.

Fourth, the waveguide creates an acoustic boost in the midrange. This allows you to reduce the electrical signal on the tweeter in this range and reduce the non-linear distortion of the HF link at low frequencies.

Just to swap out your stock tweeter for a different one because "new is better" is a bad idea. Filters in the loudspeakers are tuned for specific speaker models, taking into account its frequency response curvature, input impedance, sensitivity, and phase response.

A simple substitution can create a "wow effect" at first. For example, the treble became more transparent and louder. But immediately after mitigating the "wow effect", side effects can attract attention: wrong tonal balance of voices and instruments, changes in the vertical directional pattern of the mid-high frequency range. You can persuade yourself that "well, the new tweeter is better, so everything should sound like that, I just didn`t know this before."

However, practice shows that these persuasions do not last long, wrong timbres annoy over time, after which the search for a specialist who can correct the situation begins. To replace a tweeter with a decent result, you need experience in setting up speakers, measuring equipment (measuring microphone, measuring software and hardware) and the ability to work with it. Therefore, even before buying tweeters, you need to find a specialist and discuss with him the possibility of replacing and adjusting the speaker filters for such an upgrade.

A second (or more) order filter is strongly recommended. However, a first-order filter is allowed under certain conditions. Of course, we are talking about a high crossover frequency - 5 kHz and higher. It is necessary to calculate the filter in such a way that at full volume the voltage on the tweeter does not exceed the values indicated on the graph of the maximum allowable voltage. Even more desirable is that the input voltage does not exceed HALF of the maximum voltage. So the resource of the tweeter will be higher.

In practice, a 0.5 - 1.5 uF capacitor is used as a first-order high-pass filter. Most often, in such connection, the tweeter works as a super-tweeter, compensating for the HF drop in full-range speakers.

With active filtering, the speaker is connected directly to the power amplifier (PA), and the required frequency response is formed, as a rule, in the preamplifier, before of the PA.

It is important to remember that ribbon speakers are extremely sensitive to abnormal low-frequency signals at the input. These signals are "bursts", "steps", etc. formed when the PA is turned on and off. And also with external interference affecting the PA - power supply, radio frequency interference (probably everyone is familiar with the interference that a cell phone creates, lying on audio equipment).

You can assume that your amplifier never produces any bass burst. Or they are too small to worry about and connect the tweeter without protection filter circuit :(

However, practice has shown that constantly acting imperceptible bursts of low frequencies, which do not cause noticeable damage to the membrane, can eventually use up the margin of safety of the membrane, and in a couple of years the membrane will fail.

Therefore, be sure to connect protective circuits!

The only reliable protection against abnormal low-frequency signals is a filter between the PA and the tweeter, which filters out low-frequency signals. The most reliable option is a capacitor. If for some reason the capacitor is not suitable, an LR circuit can be used. As in the right diagram.

The capacitance of the protective capacitor is 10-20 microfarads. More than 20 uF should not be connected, so as not to reduce the effectiveness of protection.

The LR circuit is calculated from the desired cutoff frequency.

At the same time , value of R in formula IS NOT just the value of the resistor R3 in the circuit. R value should be considered as a parallel connection of the protective resistor and the input resistance of the speaker.

Example. It is necessary to provide a cutoff frequency of the LR circuit at a frequency of 1.5 kHz at a level of -3 dB for an SRT -7 speaker with a nominal input impedance of 8 ohms. We select the value of the protective resistor 3.3 ohms.

We calculate R = (8 * 3.3) / (8 + 3.3) = 2.34 Ohm.

Then the value of the inductor

L = 2.34 /( 6.28*1500) = 0.25 mH

The coil should not be wound with a thin wire. The lower its DC resistance, the better it protects the speaker from the lowest frequencies. You can also put a resistor in series with the tweeter. For direct current, an additional divider is formed with a suppression coefficient of more than 20 dB. This will also unload the tweeter's DC transformer, since the input impedance of the tweeter is less than 0.1 ohm DC.

This is perhaps the most common beginner mistake. A bad decision is to simply make a suitable size hole in the front panel and screw the speaker on with screws. In this case, the flange will protrude above the front panel of the speaker and form very interesting bends in the frequency response, causing bewilderment: why is the frequency response so different from the declared one?

Install the tweeter flange FLUSH with the speaker front panel. This is important. Below are pictures and graphics taken from the Troels Gravecen website http://www.troelsgravesen.dk/measurements.htm

The front panel of the loudspeaker itself is the cause of diffraction of radiated waves, and strongly affects the frequency response of the tweeter due to the interference of direct waves from the tweeter and reflected waves from the edges of the cabinet. Therefore, do not complicate the situation by installing the tweeter NOT flush .

When measuring the frequency response of our tweeters, they are installed in a shield measuring 600 * 800 mm with an offset from the center of the shield. This setting has minimal effect on the frequency response of the tweeter in the range above 500 Hz. In narrow speaker front panels, the effect of diffraction is noticeable at higher frequencies. And this has to be taken into account when designing the AS. To model flat speaker front panels, the EDGE program can be recommended. https://tolvan.com/index.php?page=/edge/edge.php

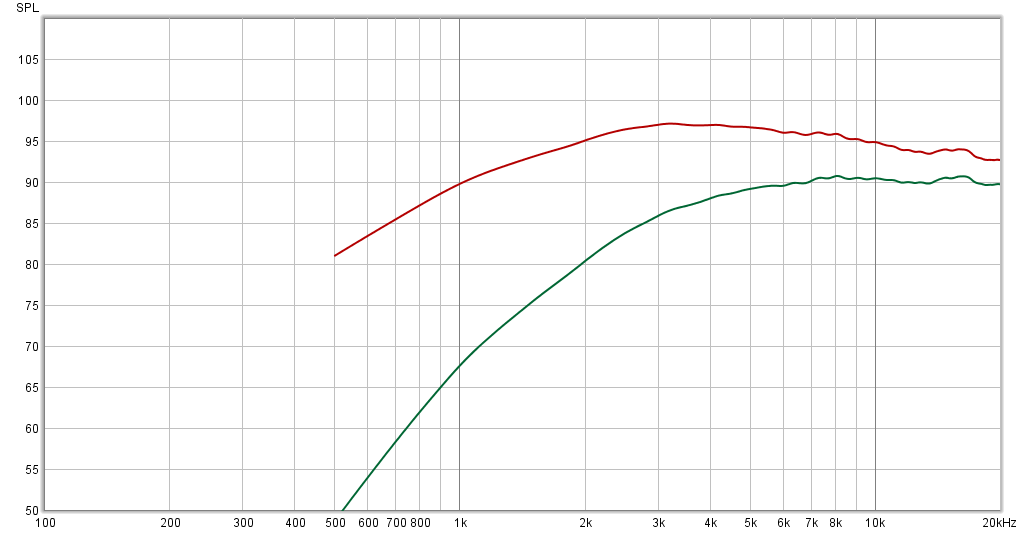

A typical frequency response of a pair of GRT-145W-8 tweeters looks like this.

Often, beginners immediately reject such a frequency response, not understanding why anybody even produce tweeters with such a hump in the frequency response in the midrange?

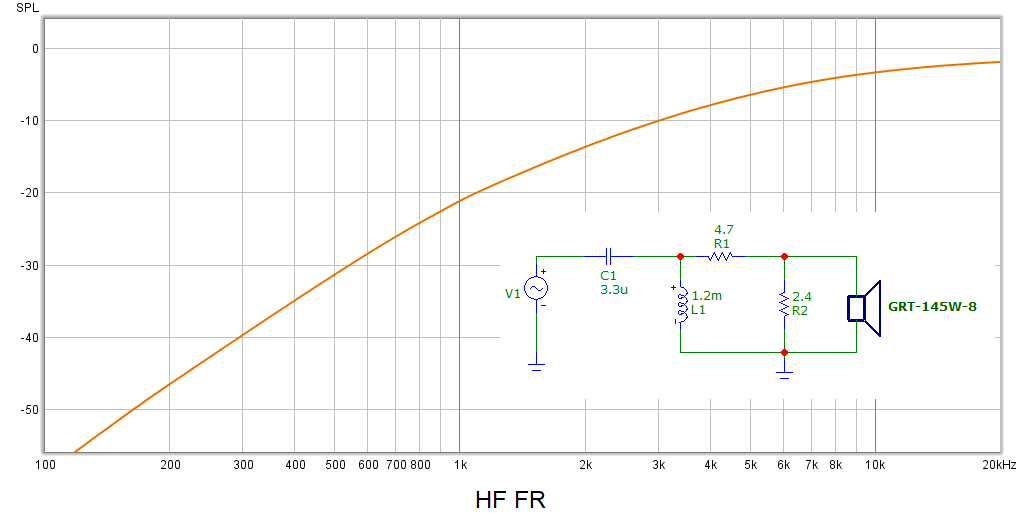

Everything is simple. The filter for such a tweeter is designed with a smooth low-frequency roll-off. Such a blockage compensates for the hump of the frequency response of the tweeter and makes it convenient for pairing with the midrange link. An example of such a filter and its transfer characteristic.

Below is the tweeter frequency response in its original form (red graph), and the final frequency response of the tweeter after applying such a filter (green)

It can be seen that the decrease in the frequency response of the tweeter at a level of -6 dB falls at a frequency of 2.5 kHz, and in the operating band on the frequency response we get the "shelf" we need. There are different techniques for constructing filters, but they all boil down to the fact that the filter's frequency response corrects the tweeter's frequency response as needed for a particular project.

Below is an example of a correction circuit for connecting a GRT-145W-8 to an amplifier with active filtering. A protective capacitor and a corrective RC circuit are connected in series with the tweeter.

Graph of the final frequency response of the GRT-145W-8 without taking into account the influence of the loudspeaker box.

If the crossover is active, then similar techniques are used in the filter to obtain the resulting frequency response of the tweeter. In this case, it is necessary to connect the tweeter to the amplifier through a decoupling capacitor, since the tweeter has an input impedance of less than 0.1 ohm in direct current. In addition, the capacitor will protect the tweeter from output voltage surges in the PA, which can damage the tweeter membrane.

This is a very common question. And fair. Due to our naming logic (or lack of it), a natural question arises for a person: if a manufacturer added a waveguide to GRT-145 and got GRT-145W, then why not add a waveguide to SRT-7 and get SRT-7W?

This idea is obvious, but it is wrong. Perhaps we should have called the GRT-145W something else... For example, SRTW-145. This would show that the model has little in common with the GRT-145.

The fact is that the GRT-145W is a separate development. The waveguide was designed with the requirement for uniform off-axis recoil reduction. And then the rear chamber was tuned taking into account the characteristics of the waveguide.

The GRT-145W waveguide has an important feature. It has minimal effect on the axial radiation of the tweeter at the highest frequencies 14-24 kHz. This is done on purpose to keep the tweeter's on-axis sensitivity in this range.

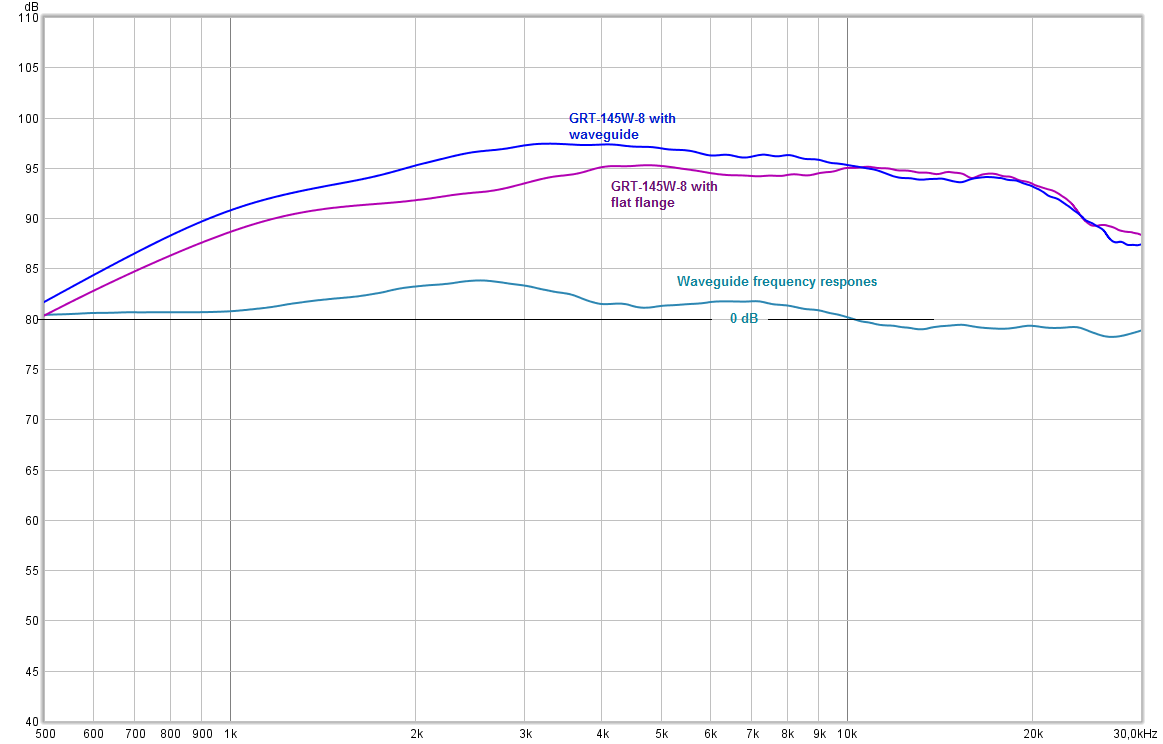

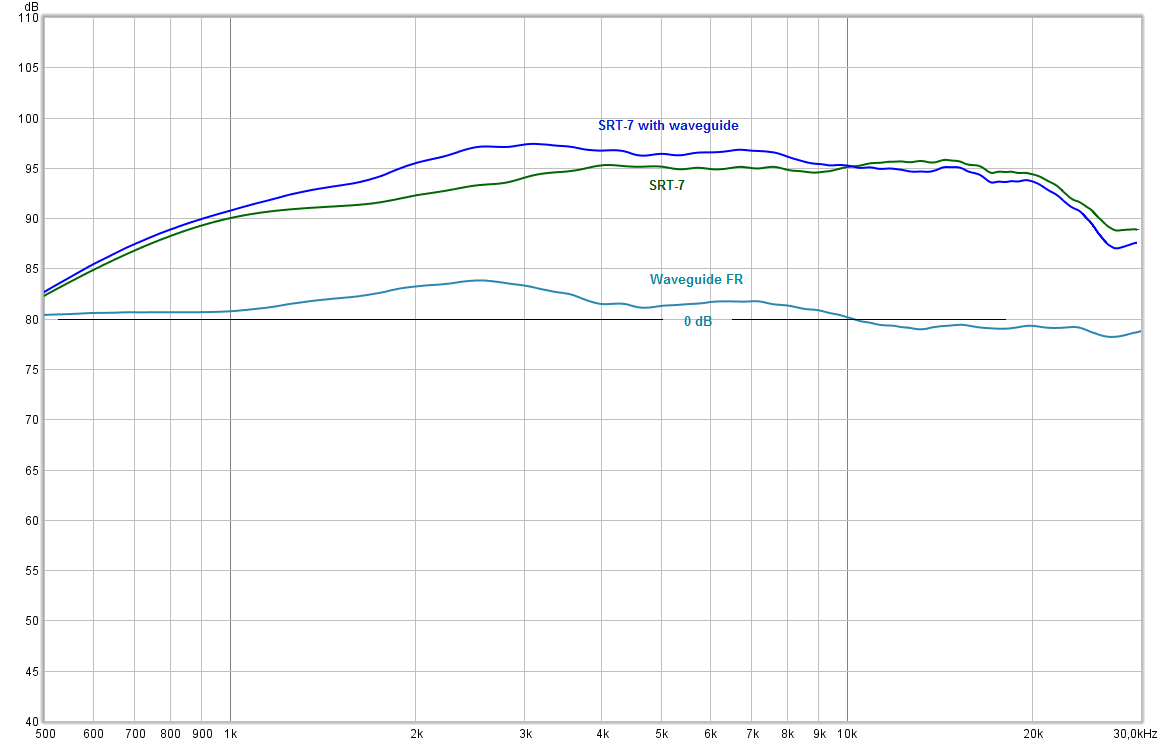

To do this, a special surface shape is used in the waveguide. But the consequence of this is an insufficiently monotonous frequency response of the recoil amplification on the tweeter axis. The waveguide frequency response from the GRT-145W is shown below . It can be seen that the frequency response has a slightly undulating character.

The GRT-145W uses a special rear chamber filling to compensate for the waveform of the waveguide.

Therefore, the final frequency response of the GRT-145W tweeter is very flat. Such a frequency response does not require equalization in the filter and allows you to build a filter with a minimum number of elements, which has a very good effect on the final sound of the tweeter.

Below are graphs of the frequency response of the waveguide (turquoise), the frequency response of the GRT-145W-8 (blue) and the frequency response of the GRT-145W-8, which has a flat flange instead of a waveguide (lilac)

From these graphs, it is clear that in the GRT-145W, the waveguide and the rear chamber work in conjunction with each other.

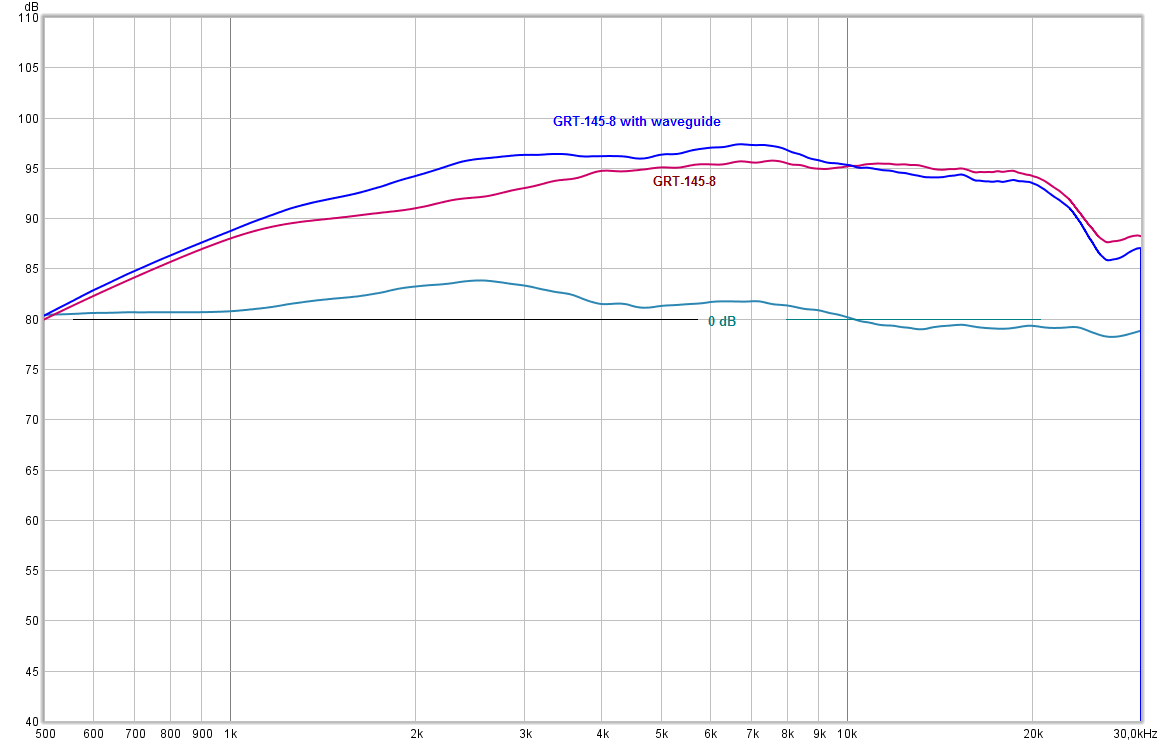

Below are the frequency characteristics of the GRT-145-8 and SRT-7 when they are equipped with a waveguide from the GRT-145W. The pictures show that the final frequency response of such tweeters will be less smooth than that of the GRT-145W tweeter.

The resulting frequency response graphs when the waveguide is installed on the SRT-7 and GRT-145-8, in comparison with the frequency response of the GRT-145W-8. To improve the visibility of differences, the scale is increased - 2 dB per division.

Structurally, the GRT-145W is closer to the SRT-7, and not to the GRT-145. Because the GRT-145W and SRT-7 use rear chamber sectioning.

The variety of mids and midwoofers is now so great that it is impossible to give exact recommendations. It is advisable to take a midrange (LF-MF or SHP ) speaker with high resolution in the operating band and at the crossover frequency.

What is this strange term "resolution"?

In fairness, it should be noted that there is no consensus among audio professionals, both on the scientific nature of this term, and on the reasons that affect resolution.

Let it be the speaker's ability to produce quiet reverb tails and nuanced instrument timbres where louder sounds don't mask quieter ones. Even in mono mode, such a speaker creates the illusion of surround sound. You may ask - what prevents any speaker from having a high resolution? Apparently, something is interfering... With comparative listening, it immediately becomes clear which loudspeaker has a higher "resolution".

SRT ribbons have very high resolution, so they need a worthy partner in the midrange. In this case, the transition from MF to HF can be made harmonious in sound. If you take a mid with a low resolution, then there will be a strange defect in the musical image. At high frequencies, the listener will experience a deep image, and at midrange, a shallow one. This violates the harmony of the musical image and attracts attention, distracting the fastidious music lover from immersing himself in the musical illusion.

In part, this issue can be solved by acoustic tuning techniques. For example, a wide frequency range of joint operation of the midrange and high-frequency links, or the selection of the type of parts in the filter. But this is an attempt to correct a mistake in the choice of speakers. It is better not to make this mistake.

If the mid driver resolution is high, then "cooking" the "dish" will be easier and more enjoyable. And there will be more degrees of freedom for customization. If desired, the resolution can be reduced. It is affected by the type of elements in the filter and the entire path from the source to the amplifier. But you can't increase the resolution. If it doesn't exist, then it doesn't. You can create the illusion of an increase in resolution, for example, by raising the return in the range of 10-20 kHz, but this is still... not true, not real, not tasty.

Trying to select a mid driver only on the measured parameters and graphs is not the best option, since the set of parameters does not directly affect the resolution. You can be very disappointed. If there is not enough experience with various speakers, it is recommended to contact more experienced speaker designers for help.

Usually, speakers with a cone made of materials with low internal friction have a higher resolution: unimpregnated (weakly impregnated) paper, ceramics, metal, composite materials, etc. But the material of the diffuser does not give any guarantees. In addition, it is necessary to properly filter such a speaker in order to unlock its potential, and not lose it. And of course, there are exceptions to the rule. Therefore, the final decision is only for the auditory expertise.

And once again it should be noted that resolution is not a panacea. Excessively clear drawing of small details of the sound image can distract attention from the music itself. It is important to find a harmonious combination of the layers of the musical picture so that the listener does not have the question "why is he sawing this big violin with a bow?"

From a tweeter safety point of view, the recommended low crossover frequency is 1.8 kHz with a second-order high-pass filter. However, in each specific loudspeaker project, many factors must be taken into account. One of them is how much the harmonic distortion of the tweeter outside the operating band will contribute to the total harmonic distortion of the speaker system?

The fact is that the maximum non-linear distortion of SRT tweeters falls on the resonance frequency of the chamber. It is in the region of 700-1000 Hz. If the tweeter is not cut off well enough by the filter from this range, then the tweeter distortion at these frequencies will make a significant contribution to the overall speaker distortion, and will also cause intermodulation distortion between the midrange and HF in the tweeter radiation.

For example, if the tweeter will be used in small two-way monitors that will not develop high sound pressure, then the crossover point can be selected from 1.8 kHz and higher. If the tweeter is to be used in more powerful speakers, then it makes sense to move the crossover point higher to relieve the load on the tweeter.

In practice, according to developers, in two-way speakers, the SRT-7 and GRT-145 tweeters do well with sections of 2.5 kHz and above, GRT-145W - 2.0 kHz and above. In this case, filters of the 2nd order and the speakers are not planned to have pressure peaks above 110 dB (from each speaker at a distance of 1 meter).

The most commonly used and proven type of capacitor is the polypropylene dielectric. With foil linings, or a metallization layer on a polypropylene film. On the Internet, a lot of copies are broken in the debate, which ones are better / worse. Therefore, it is desirable to select the final model of the capacitor already in the finished and combined pair of speakers.

There are many types of capacitors. Differences in weight: the thickness and type of dielectric, different metals in the linings (aluminum, copper, silver, gold, tin, etc.) and their thickness. The manufacturing technology is different - the method and force of winding tension, etc. All this affects the parameters of the capacitor (distortion, loss ....), and, as a result, affects the sound.

A bit off-topic. About resistors. Try to choose resistors in which the resistive element and terminals are connected by welding, not pressing. Such resistors have less distortion and a clearer sound.

As for the choice of the type of inductor coils. It is best to ask experienced loudspeaker designers for clarification on this issue.

Installing SRT tweeters in a car is not the best idea. You can Install these tweeters in a car, but with a number of restrictions.

The tweeters have a rather massive and long back. The way the back is attached to the flange is not designed for the constant vibration that the tweeter is constantly subjected to in a car. Therefore, additional fixation of the back is required.

Tweeters have a large area of the secondary power circuit of the transformer. For this reason, the power wiring in the car serves as a source of interference, which under certain conditions can be heard from the speakers.

The magnetic field of the speakers is very good at attracting magnetic dust. Condensation on the foil can create pockets of corrosion on the belt. It is important to prevent conditions for its formation on the surface of the ribbon.

For a number of these reasons, the use of SRT tweeters in a car is not recommended.

The magnetic system of the ribbon speaker is designed in such a way that the magnets are located immediately below the flange. The magnets are very strong. The induction inside the gap in which the ribbon oscillates is 0.65 Tesla. Believe, this is a very strong magnetic field. Even though the field is largely concentrated between the magnets, some of the magnetic field goes beyond these limits. At a distance of less than 1 cm from the gap, the field becomes already so strong that it can pull bits from screwdrivers and screws from hands. The field is pretty insidious. At a distance of 2 cm from the flange, you can calmly hold the screw with your fingers, but already 1 cm from the flange, this screw will be shamelessly torn out of your hands by a magnetic field.

Therefore, when mounting tweeters in loudpeakers are advised to cover the center of the tweeter with some non-magnetic object to prevent steel objects from entering the tweeter window. The protective grid will save the membrane from damage. But even an ordinary self-tapping screw that has fallen into the flange window leaves a noticeable dent on the protective grid. And larger items, like screwdrivers, even more so.

Ribbon tweeters do not like EXTERNAL SOUND SHOK WAVES!

Bang on the tweeter window can deform the membrane. Therefore, during transportation, the tweeter window is closed with a plug. If the loudspeakers need to be transported, it is advisable to close the tweeter windows with the same plugs, or similar ones. It is important that the sound wave from hitting the body of the box with speakers does not reach the membrane.

Please note that it is not necessary to drop the box in order to form a high sound pressure wave inside the box. It is enough, for example, to hit the cardboard box hard with the palm of your hand, or to drop a heavy object on the box. Externally, the box may remain intact after impact, but a strong sound wave will be generated inside, which can damage the unprotected membrane.

Tweeters are packed in a matched pair in one corrugated cardboard box. When shipping, this box is placed in a larger box for better preservation.

SRT membranes are quite reliable. With proper operation, they delight music lovers with the sound for years without any incidents. However, it happens that the membrane is damaged for some reason. The membrane can be replaced. This is provided by the design of the tweeter. However, the replacement procedure requires accuracy and some manual dexterity. Therefore, it is advisable not to bring the matter to the replacement of the membrane.

If we analyze the requests of customers who request a spare membrane, then in most cases the membrane is damaged by the customers themselves after disassembling the tweeter. Of course, disassembling the tweeter is not recommended! However, the screw connections in the tweeters look tempting, and are tempting some keen audio enthusiasts to disassemble the tweeter.

Once again - we strongly do not recommend disassembling the tweeter!

Some of the cases of membrane damage are due to testing tweeters with violation of safe modes and errors when connecting tweeters to speakers. For example, an erroneous connection of a tweeter to a woofer filter. Therefore, it is recommended that after connecting the speakers, listen to the speakers at a minimum volume and make sure that all speakers are connected correctly. And only after that increase the volume to the desired level.

If it came to disassembly, you need to remember that in the magnetic gap of the tweeter there is a strong magnetic field - 0.65 Tesla. At the same time, it is very insidious. The field decreases rapidly with distance from the gap. And it doesn't seem to pose any threat. But the problem is that if you bring the screw to the gap at a distance of 2 centimeters, it is calmly held in your hands, and at a distance of less than 1 centimeter, the magnetic field pulls this screw out of your hands and it instantly makes a hole in the membrane.

The same goes for screwdrivers and removable bits.

You need to be extremely careful when using removable bits. The magnetic field easily pulls the bits out of the screwdriver holders, so the bits must be securely fixed in the screwdriver. Adhesive tape, glue, gasket...

Almost all the screws used in the assembly of tweeters are DIN 7500. In fact, these are "self-tapping screws" with metric threads: they are hardened and extrude the threads in the hole. When a screw cuts into a hole, metal chips can form during the first revolutions. The chips bind with grease and remain close to the hole. After unscrewing the screw, carefully remove it and wipe off the remaining lubricant with chips, since chips flying into the magnetic gap can leave dents on the membrane.

After unscrewing all the screws, the flange must be removed in such a way that any chips remaining at the holes do not fall into the magnetic gap.

A video with the procedure for replacing the membrane in SRT tweeters is on Google Drive at this link https://drive.google.com/file/d/1_n-5M-yH2WQZjV-xw0Nt5JwsC9oP8gTG/view?fbclid=IwAR2FD9gFvL39yAf2t8lkTyxlZ7-YlqNwDGJ3dAziUs1aaO8ycpR7hHKI